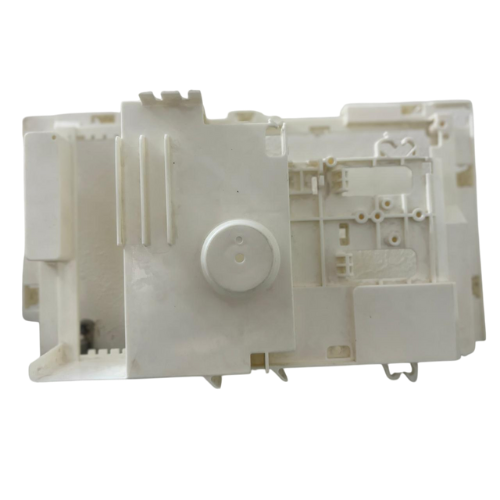

Leopard Polymers is a trusted name in the consumer electronics, home appliances, pharma, and automotive industry. We specialize in delivering high-quality plastic injection moulded components and PU spray-painted parts.

Our objective is to supply high-quality products with commitment, precision, and consistency.

| Machine | Tie Bar (H × V) | Mould Height | Shot Weight |

|---|---|---|---|

| FCS 570 | 820 × 800 mm | 250 × 800 mm | 1554 gms |

| FCS 250 | 555 × 555 mm | 200 × 670 mm | 429 gms |

| Milecron 100 | 300 × 300 mm | 200 × 490 mm | 100 gms |

A quick look at our manufacturing setup, machinery, and polymer processes.

We deliver excellence with expertise, commitment, and innovation.

Our engineers, designers, and project managers bring deep expertise and hands-on experience to deliver the best results.

We strictly follow all safety norms and adhere to international quality standards in every project we execute.

With cranes, boom lifts, scissor lifts, welding machines and more, we ensure faster execution with full project control.

We value deadlines and are committed to completing every project on schedule with maximum efficiency.

Every project is unique — we offer tailored engineering and equipment solutions as per client needs.

Our work philosophy is built on trust, transparency, and long-term partnerships with our clients.